How We Treat Sharps Waste

Sharpsmart developed and patented the unique Effluent Retention System – a revolutionary sustainable alternative treatment solution for medicinally-contaminated sharps waste.

Our Effluent Retention System:

-

Validates sharps waste for alternative treatment.

-

Provides a sustainable alternative to high-temperature incineration.

-

Has a permitted capacity of 8,000 tonnes per annum – and is growing.

In 2022, we treated 2,080.97 tonnes of sharps waste – saving 1,132.05 tonnes of CO2e

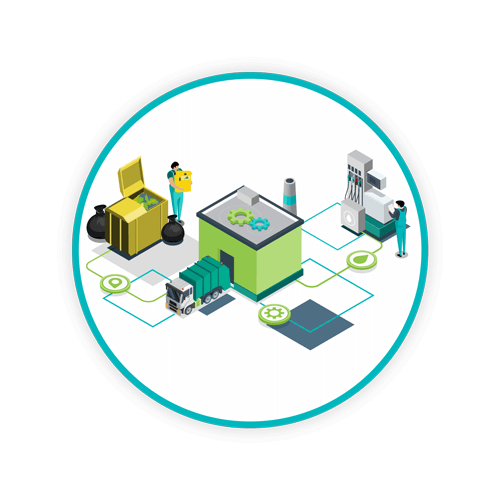

What Is the Effluent Retention System?

The Effluent Retention System (ERS) is Sharpsmart’s patented Sharps Treatment Solution that merges environmental responsibility with healthcare efficiency and compliance. This closed-loop process uses shredding, sterilisation, and a unique Effluent Retention System to ensure there’s no discharge of effluents to air or sewer throughout treatment.

The Effluent Retention System is a sustainable alternative to high-temperature incineration, with the capability of treating over 2 tonnes of hazardous sharps waste per hour. It was born from a combination of factors:

-

Our intimate understanding of sharps waste.

-

Our commitment to a safer and more sustainable healthcare industry.

-

Our dedicated support of the NHS and the entire healthcare industry.

What Sharps Waste Can The Effluent Retention System Process?

Our Sharps Waste Treatment System was designed to process sharps waste under European Waste Codes:

-

EWC 180103*

-

EWC 180103*/09

Note: Above are the types of sharps waste processed using Sharpsmart’s Effluent Retention System, however, we’re fully capable of treating all sharps waste including EWC 180101.